Test House Services

At TS-Space Systems we have over 30 years experience in designing, building and operating vacuum systems for space simulation and materials testing ranging from ion thruster test chambers to orbital simulation and rapid thermal cycling.

We have three in-house thermal vacuum (TVAC) chambers which are configurable for a range of temperatures for either monitored vacuum bakeout or thermal vacuum cycling. We design, build and operate these systems in-house which means we are more flexible than most test houses and are happy to modify feedthroughs, manufacture additional support equipment and even change the operation of the chambers, where possible, in order to accomodate customer requirements.

Our vacuum UV chamber was designed and built by us for the ESA Solar Orbiter mission and we have continued to upgrade and improve the capability of the aparatus at the request of our customers over the years following.

Our outgassing test facility is listed as an ESA ‘trusted laboratory’ for conducting outgassing tests to the ECSS-Q-ST-70-02 standard.

Thermal Vacuum Bakeout

-

Ensuring proper vacuum bakeout of flight hardware is increasingly important to mission success. Our thermal vacuum chamber is regularly operated for monitored vacuum bakeout of test and flight hardware to ECSS-Q-ST-70-01. Our chambers are locaed inside a HEPA filtered air room so flight hardware or sensitive samples can be loaded.

We also have an in-house FTIR facility for processing molecular contamination witness plates in accordance with ECSS-Q-ST-70-05C.

The chamber is fitted with a temperature controlled quartz crystal monitor (TCQCM) and a cold plate for contamination inspection and monitoring. TCQCM is analysed to determine bakeout completion as per ESA guidelines and ECSS-Q-ST-70-01.

The chamber can also be configured with a number of shrouds and thermal plates allowing thermal bakeout services up to +500 degrees C for a range of sample positions within the chamber e.g. flat plates, hanging samples, spools for thermocouples etc.

Pressure gauges, temperature data (calibrated on request) and TCQCM data are logged and provided to the customer along with TCQCM analysis if required. RGA (mass spectrometry) is also available on request.

The chamber can be remotely operated and monitored and automatic, over-temperature shutdown systems are in place to protect samples. The control and pump systems are protected by a UPS which allows a controlled shutdown in the event of power failure and notifies TS-Space Systems staff via several mobile communications channels.

-

Specimen length [mm]: 450.0

Specimen width/dia [mm]: 540.0

Specimen height/thk [mm]: 350.0

Mass max. [kg]: 20.0

Higher temperature [K/°C]: 573.15K / 300°C

Lower temperature [K/°C]: 83.15K / -190°C

Thermocouple, RTD, Fluid, Power, (additional at request)

Data acquisition: Temperature, pressure, QCM frequency, RGA

Vacuum limit [Torr]: 1E-7

-

PID controlled thermal plate with resistive heating and liquid channels for cooling either by chiller circulator or LN2

Thermal shroud with LN2 cooling and IR heating

Cold trap with removable fascia for lab analysis if required

QCM for bakeout monitoring

Residual Gas Analyser (Hiden Analytical)

Standard 13 T-type thermocouple channels (more channels, or different TC types can be added with notice)

Temperature, pressure, QCM and RGA all logged digitally

Scroll pump and magnetically levitated turbo molecular pump meaning a completely oil-free pumping system

-

TVAC#1

Solar Orbiter

TVAC#2

Solar Orbiter

Solar Orbiter - STIX

JUICE

Thermal Vacuum Cycling

-

We offer thermal vacuum cycling to ESA ECSS-Q-70-04C in both our TVAC#1 and TVAC#2 thermal vacuum test chambers (TVAC#3 planned to join the lineup in 2024).

Temperature cycles, pressure, TCQCM and RGA data (if required) are logged on a PC data acquisition system. Our chambers are locaed inside a HEPA filtered air room so flight hardware or sensitive samples can be loaded.

Both chambers can be fitted with a range of thermal plates and shrouds with a maximum temperature range of +500 degrees C to -200 degrees C (nominal LN2 temperature depending on the thermal load of the sample).

Both chambers are fitted with a magnetic levitation turbo molecular pump and backing scoll pump meaning the systems are oil free. A cold plate is fitted within both chambers for contamination monitoring if required.

All of our test chambers can be remotely operated and monitored and automatic, over-temperature shutdown systems are in place to protect samples. The control and pump systems are protected by UPS which allows a controlled shutdown in the event of power failure and notifies TS-Space Systems staff via several mobile communications channels.

-

Specimen length [mm]: 450.0

Specimen width/dia [mm]: 540.0

Specimen height/thk [mm]: 350.0

Mass max. [kg]: 20.0

Higher temperature [K/°C]: 573.15K / 300°C

Lower temperature [K/°C]: 83.15K / -190°C

Thermocouple, RTD, Fluid, Power, (additional at request)

Data acquisition: Temperature, pressure, QCM frequency, RGA

Vacuum limit [Torr]: 1E-7

-

PID controlled thermal plate with resistive heating and liquid channels for cooling either by chiller circulator or LN2

Thermal shroud with LN2 cooling and IR heating

Cold trap with removable fascia for lab analysis if required

QCM for bakeout monitoring

Residual Gas Analyser (Hiden Analytical)

Standard 13 T-type thermocouple channels (more channels, or different TC types can be added with notice)

Temperature, pressure, QCM and RGA all logged digitally

Scroll pump and magnetically levitated turbo molecular pump meaning a completely oil-free pumping system

-

TVAC#1

Solar Orbiter

TVAC#2

Solar Orbiter

Solar Orbiter - STIX

JUICE

Vacuum UV Testing

-

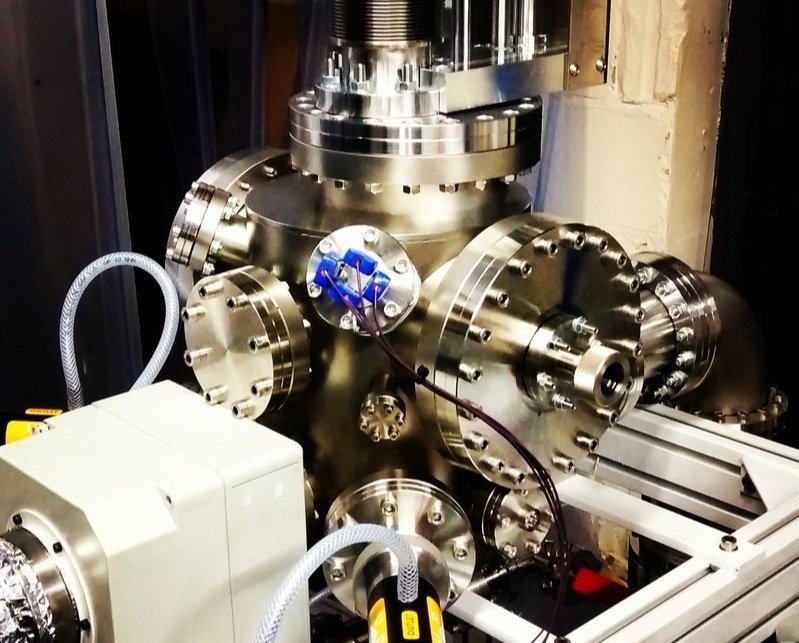

The system consists of a high-vacuum chamber, multi-ported, equipped with deuterium and xenon sources for accelerated ageing of coatings under vacuum.

The specimen to be irradiated is mounted on a temperature-controlled platen, which, in turn is mounted on a XYZ J manipulator. Provision is made for the measurement of emissivity and absorptance without breaking vacuum and at the operating temperature.

The chamber is fitted with a magnetically levitated turbo molecular pump and scroll backing pump meaning the system is oil free.

-

Maximum operating temperature of sample: 600 degrees C. Specified by customer

Sample size: Four 25x25mm

Total number and time of emissivity and absorptance measurements specified by the customer

Samples are held under high vacuum

-

Temperature monitored and logged via three calibrated K-Type thermocouples for the duration of test

Emissivity measured to better than +/-0.01

Percentage change in absorptance

Mass spectrometer data

The chamber can be remotely operated and monitored and automatic, over-temperature shutdown systems are in place to protect samples.

The control and pump systems are protected by a UPS which allows a controlled shutdown in the event of power failure and notifies TS-Space Systems staff via several mobile communications channels.

Emergency chamber sealing and Argon fill systems can also be engaged.

-

Solar Orbiter

Outgassing Testing

-

Our outgassing facility is built to NASA and ESA specifications and has been approved by ESA as a trusted laboratory for ECSS-Q-ST-70-02C outgassing activities.

Tests are run to ECSS-Q-ST-70-02C 2008 issue (previously ECSS-Q-70-02A, generic ECSS-Q-70-02).

Twelve cells (two blocks of six) are available per run.

A report of mass loss and gain is produced with annotations where anomalies or unexpected results arise.

Please note: your material or product have already been tested/approved. It is worth checking the SPACEMATDB database which searches across multiple outgassing databases.

-

Sample positions for three samples of each of three materials (9 cells)

One empty cell per block (2 cells)

Temperature and pressure data digitally logged

-

Built to NASA/ESA specifications

ESA trusted laboratory for ECSS-Q-ST-70-02C after collaboration in the inter laboratory activity in 2018-2019 ‘round-robin’

“Oxford Space Systems has used TS-Space’s services since 2015. Their consistent efficiency, clear communication, and flexibility to accommodate our deployable antenna project timelines makes them the ‘go-to’ test facility for OSS’s outgassing test needs. Based on their excellent service, I would be happy to recommend TS-Space to any organisation seeking a dependable test facility.”